From Zero to One. Gardin’s plant driven growing platform.

Context

An old college friend and entrepreneur approached me about a non-destructive way to assess produce quality using chlorophyll fluorescence (ChlF). Our goal was to turn a ~$100K lab method into a sub-$100 field sensor and a software-as-a-service (SaaS) product. The hard parts were proving a reliable correlation between ChlF signals and plant health in controlled environments (greenhouses, vertical farms) and defining a clear value proposition and pricing for a risk-averse agriculture market. Despite the UK (United Kingdom) leaving the EU (European Union), global electronics shortages, the Silicon Valley Bank (SVB) collapse, and a UK venture-capital (VC, venture capital) slowdown, we stayed focused on proving feasibility, securing capital, and building a credible 0→1 path to the first 1,000 units.

Actions

Over 3.5 years, I partnered closely with the CEO and collaborated across functions to take the idea from concept to first product: we framed testable hypotheses around chlorophyll fluorescence (ChlF, chlorophyll fluorescence) as a proxy for plant stress and how it would deliver value to growers, built the investment narrative, and raised $1M to fund a proof of concept (PoC). Together with our photonics physicist, embedded/robotics engineer, plant biologist, and operations specialist, I led iterative prototyping and placements in leading United Kingdom (UK) plant-science labs, while running product discovery with growers to define value, pricing, and workflows. Working with the broader team and partners, we expanded funding, planned the first 1,000-sensor build with supply chain and quality assurance (QA), secured channel partnerships for distribution, and used design thinking to mitigate external shocks.

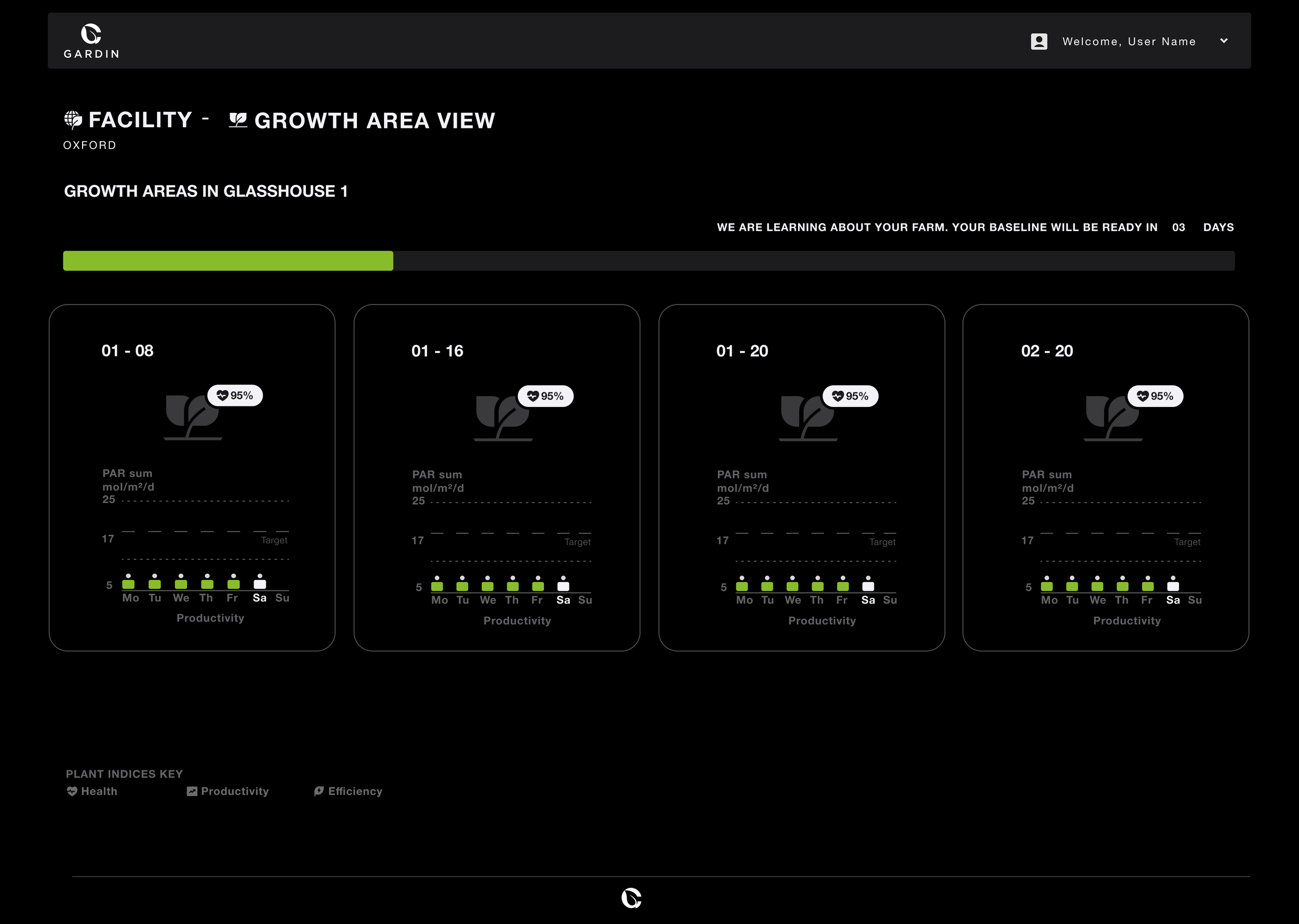

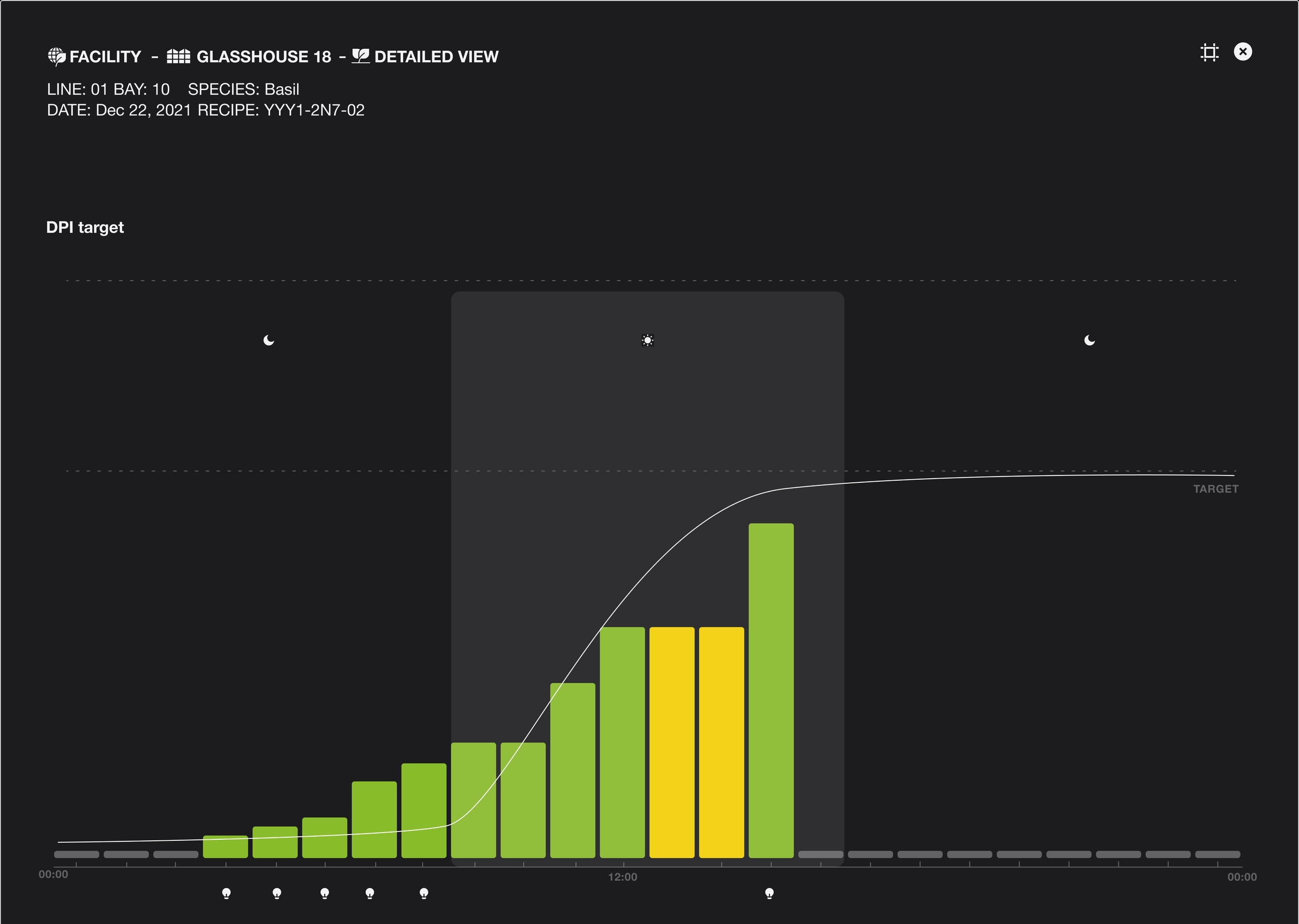

Clear value proposition: early intervention. Gardin detects issues up to two weeks before visible symptoms appear; correcting them at that point saves 1–2 weeks in the growth cycle.

Results

We validated the technology in lab and early field pilots, demonstrating repeatable ChlF measurements correlated with plant-health indicators and usable grower workflows—supporting a pricing model grounded in return on investment (ROI). We secured $11M total seed funding, established manufacturing readiness for the first 1,000 sensors, and launched paying pilots across more than 20 farms (seed breeders, greenhouses, vertical farms) in the United States, Canada, the United Kingdom, Spain, Italy, and the Netherlands through distribution partnerships—creating a clear path from 0→1 (from concept to first product) toward scaled deployment. We defined a new category.

$11 M

Seed round raised third largest in Europe history.

20+

Installed paying farms and growing across more than 6 countries and 2 continents.

$50.6 B

Multibillion dollars serviceable available market ( SAM ) unlocked.

From zero

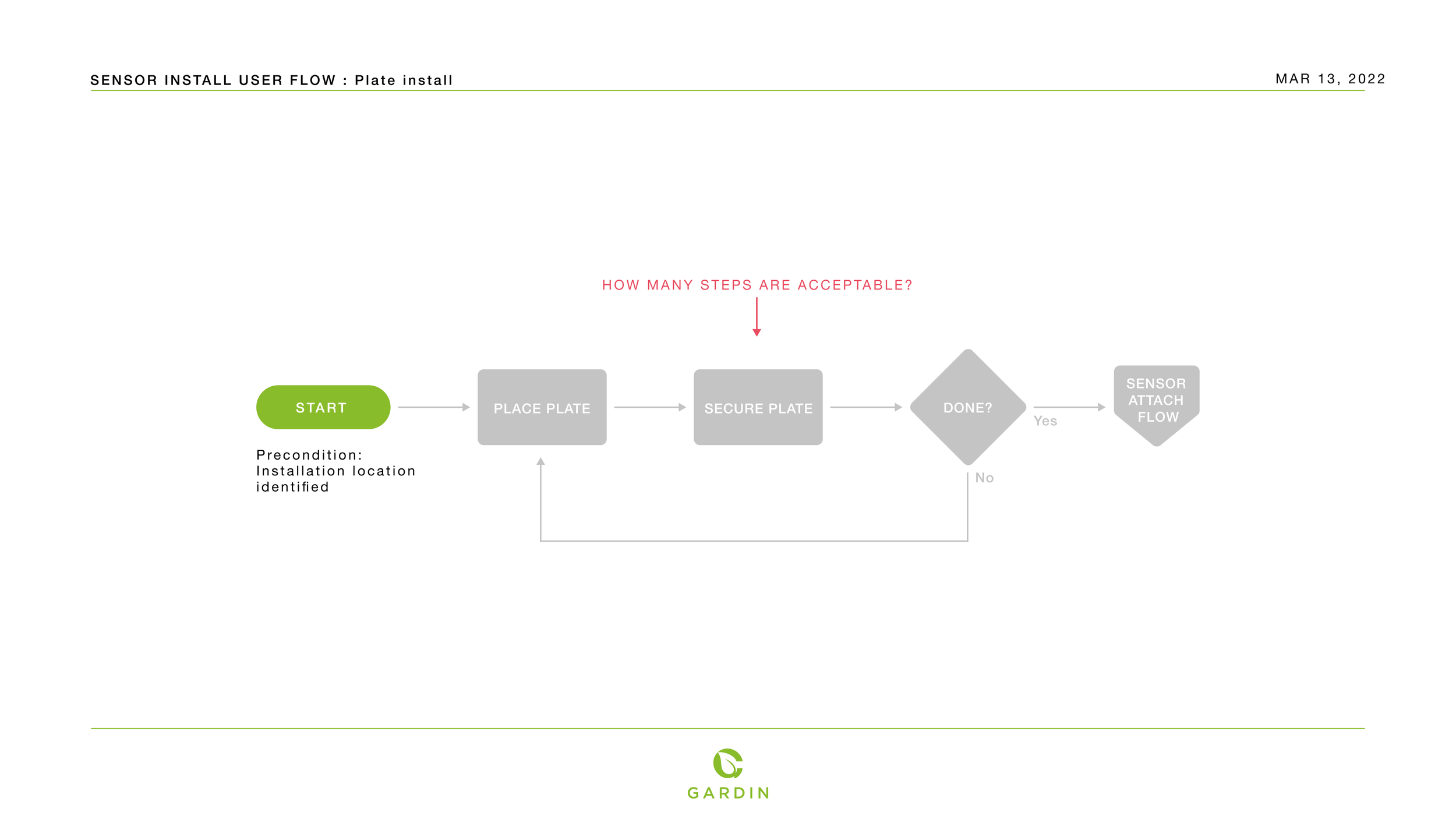

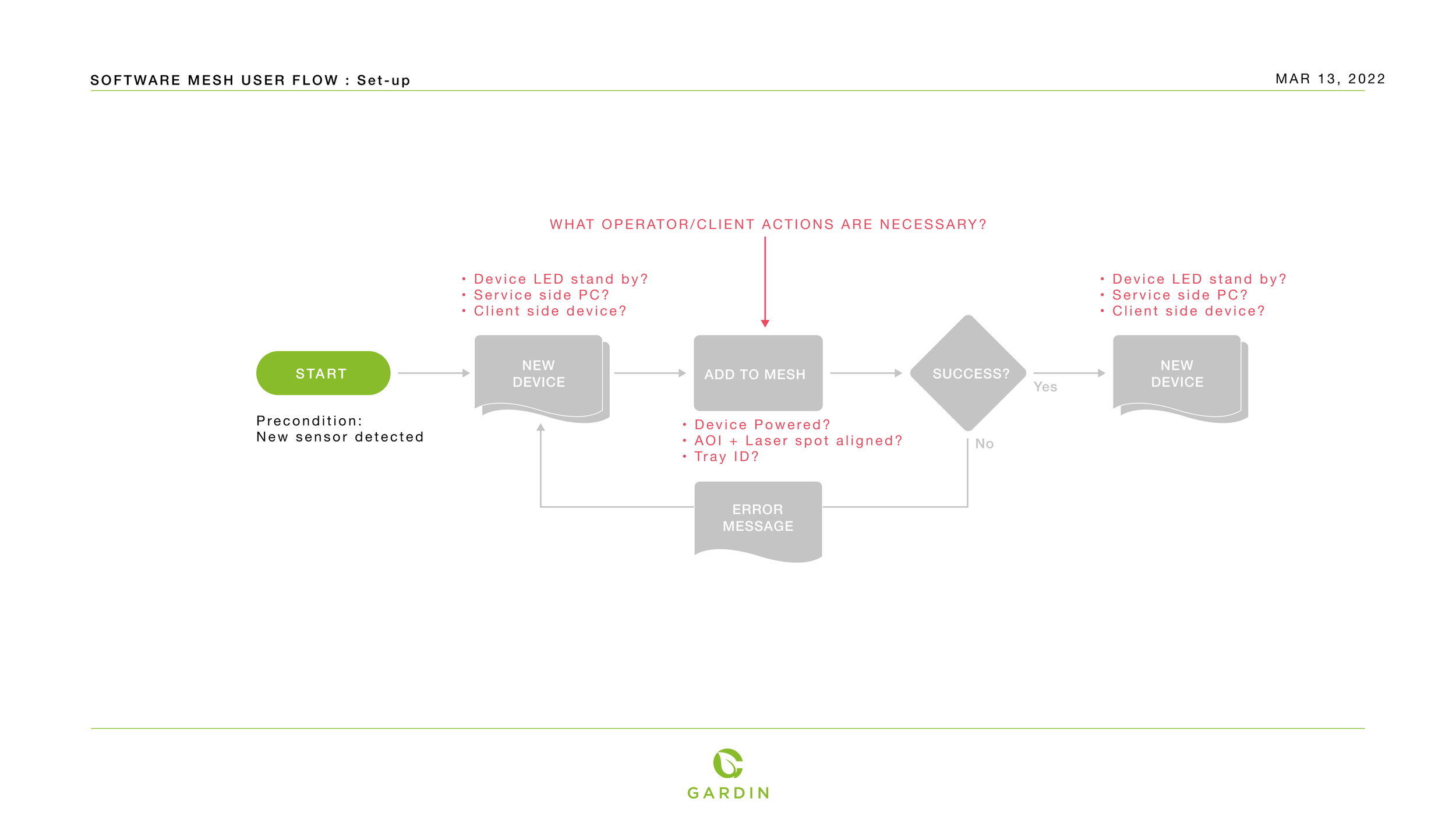

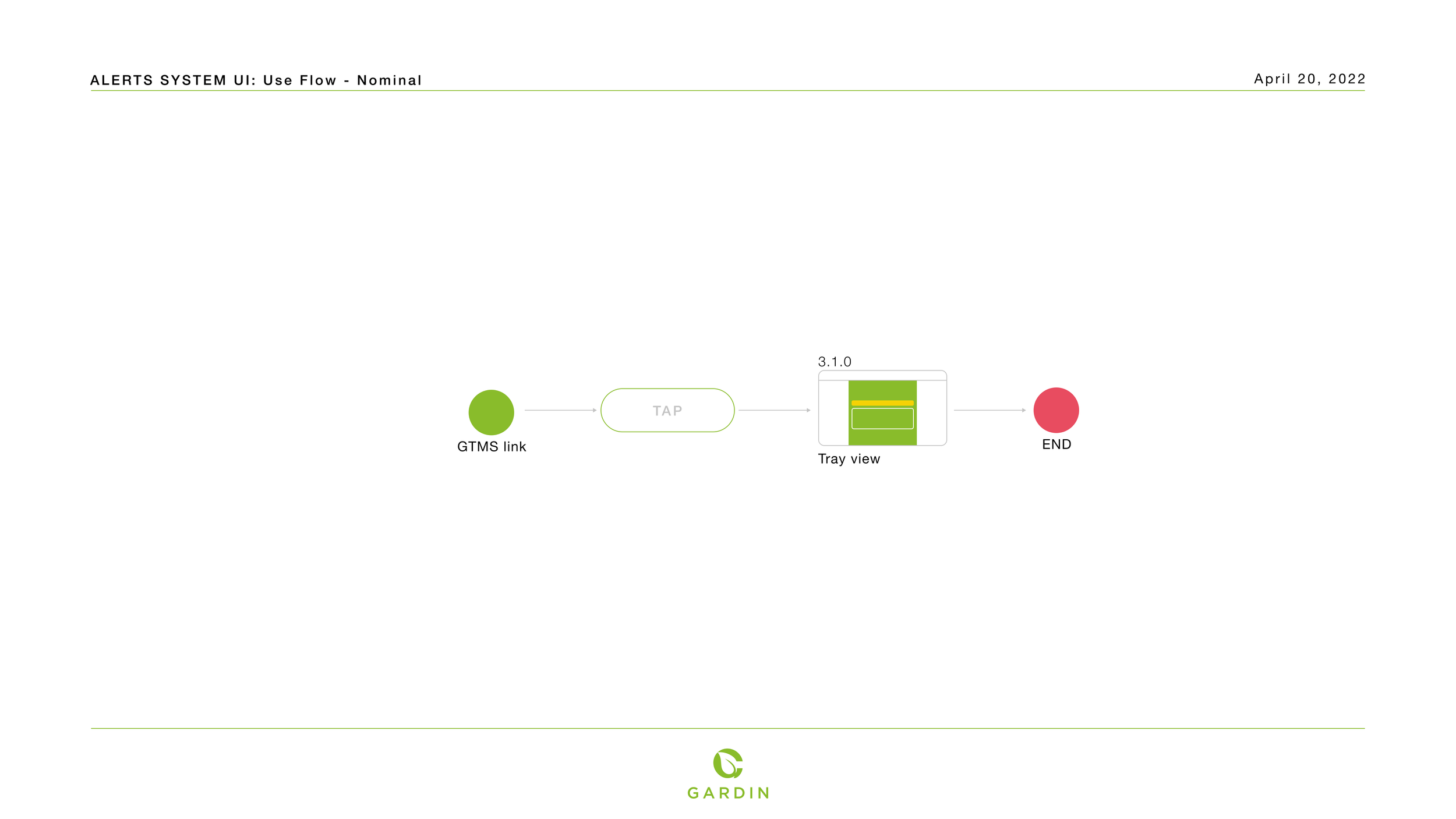

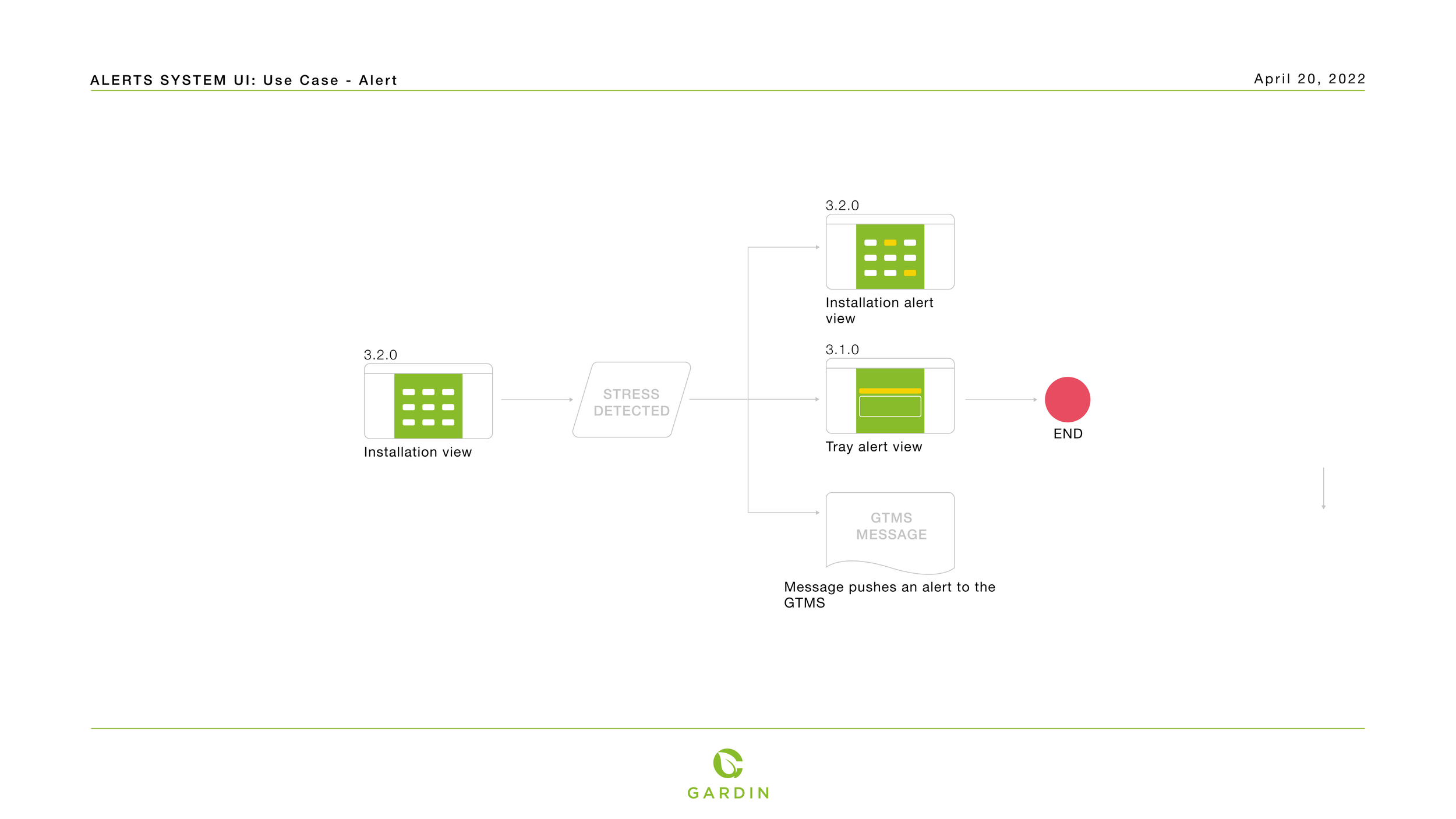

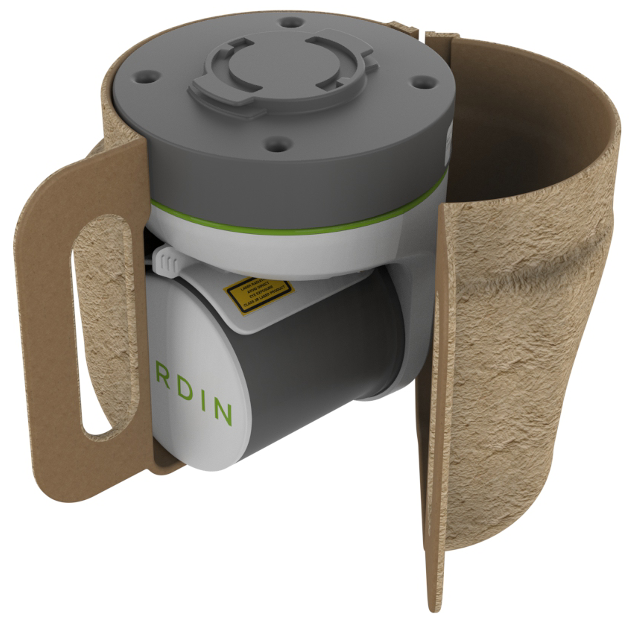

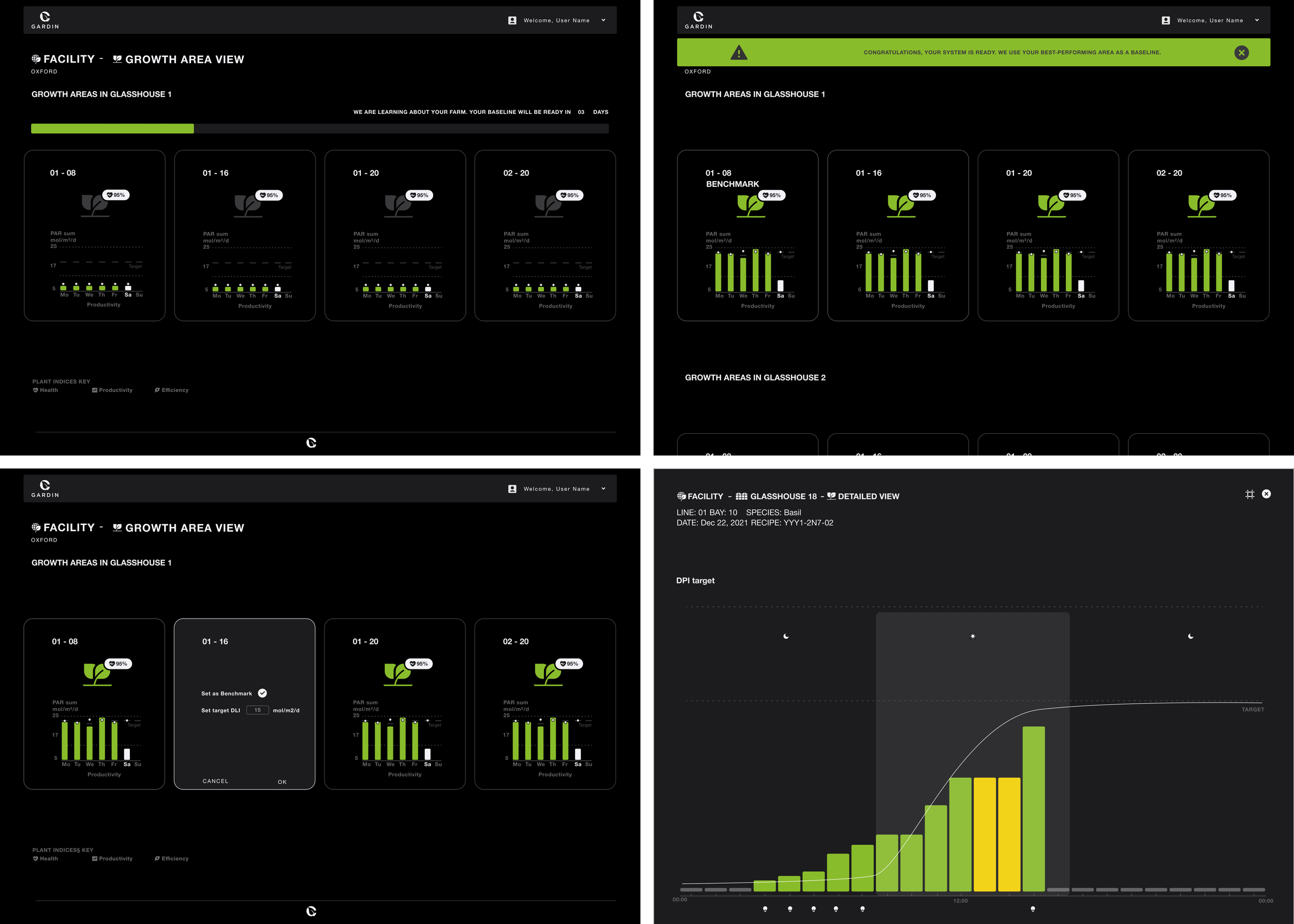

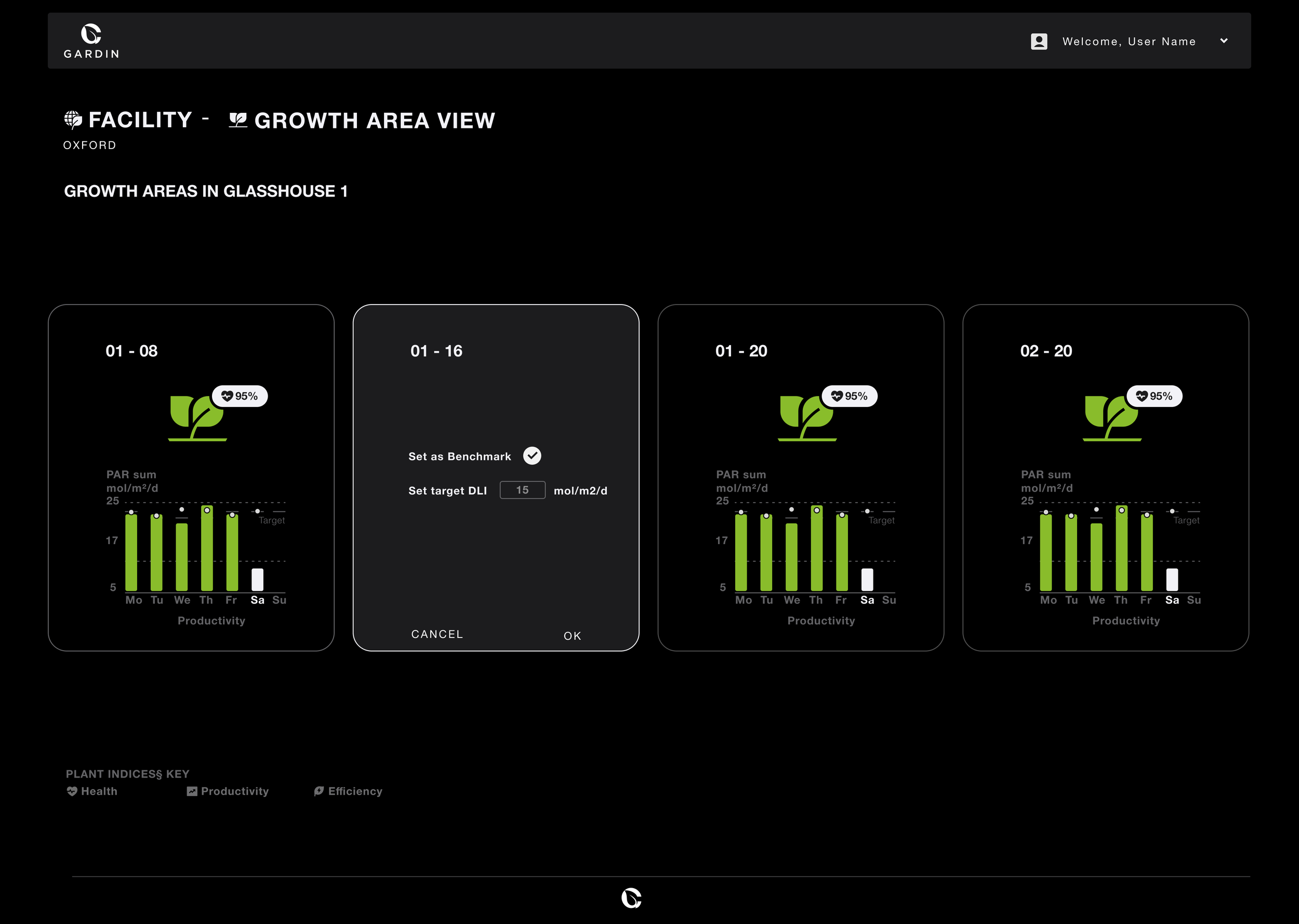

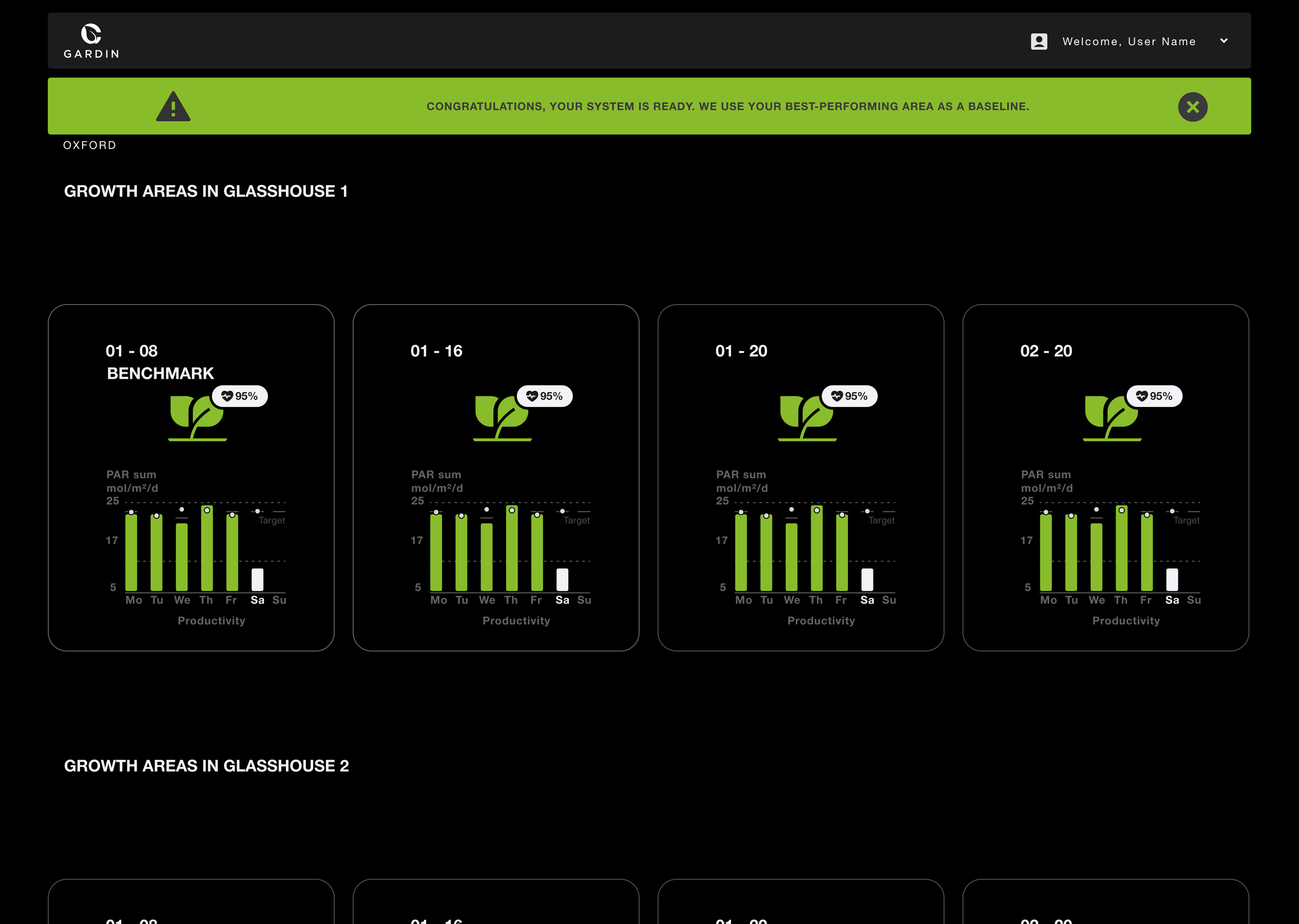

Utilizing end-to-end user flows to identify hardware requirements, software touch-points, and draft product specifications, we developed an observation protocol to systematically understand the installation process and ensure the sensor is easy to install and maintain by regular farm employees without special tools.

Gardin’s installation process emphasizes a plug-and-play approach to avoid high technical installation costs, and is robust enough to withstand environmental conditions in glasshouses, requiring minimal maintenance.

Hardware Interaction

Software interaction

Prototyping into existence. Building prototypes to gain real-world operating insights and test hypotheses early, our first iteration revealed unexpected environmental conditions effects, highlighted hardware assumption limitations, and identified critical software platform components essential for delivering a monetizable service.

“ Plant sensors that can indicate how the plant responds to all climate variables are crucial for further optimization of not only the lighting strategy but the entire greenhouse climate. ”

— Gert-Jan Dekker, lead agronomist at Agrolux

To One

While developing the software in house, I leveraged lessons from our field observations to spec the real sensor and the application UI. In parallel I managed an industrial design firm, through several iterations to develop a sensor that meets UL and EU certifications for European and North American markets.

Through progressive versioning, we’ve created a final product that is based on real-world observations and practical usability to bring profound value to our clients.